EndoPilot² ultra

EndoPilot² ultra:bestehend aus: Steuergerät: 110 2010 EndoPilot² Steuergerät mit 7" Touch-Display 110 2203 Med. Netzteil 100-240V/50-60Hz 109 2361 Funk-Fußschalter, single, bluetooth 109 2311 Apexkabel-Set 110 2303 Haltebügel für Apexkabel...

Gutta Percha Bar (100bars/box)

Gutta Percha Bar PlusInhalt: (100 Stück/Box)

Feilenklemme (zerlegbar)

Feilenklemme (zerlegbar)für Apexkabel EndoPilot

EndoPilot² ultra plus

EndoPilot² ultra plus:bestehend aus:Steuergerät: 110 2010 EndoPilot² Steuergerät mit 7" Touch-Display 110 2203 Med. Netzteil 100-240V/50-60Hz 109 2361 Funk-Fußschalter, single, bluetooth 109 2311 Apexkabel-Set 110 2303 Haltebügel für Apexkabel...

Apex-MessKabel- mit Stecker

Apex-Messkabel mit Stecker für Endopilot jedoch ohne Feilenklemme, Lippenclip, bzw. Kabel für Feilenklemme

Knochenfilter KF-T3

Titan-Knochenfilter KF-T3 zweiteiliges Titan Gehäuse mit Klammer,Spannring sowie Silikon O-Ringohne Einwegsieb • bequeme und zeitsparende Gewinnung von autologem Knochenmaterial• die besonders große Filterfläche ermöglicht maximale Saugleistung...

Neues Software Update EndoPilot² als...

Software Update EndoPilot² Version v4.205f vom 18. Dez. 2023 Neue Feilen wurden in die Datenbank aufgenommen und Feilenbilder ergänzt Die Umbenennung der Instrumentenbezeichnung in der MyFile Anzeige wurde implementiert Die Umbenennung von...

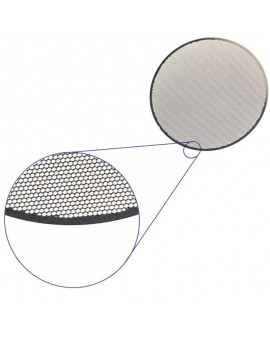

Metallfolien-Einwegsiebe (VPE 10 Stück)

Metallfolie-Einwegsiebunsteril 10 Stück je Verpackungseinheit

LippenClip

Lippenclip für Endopilot für alle Apex-Kabel

Kabel für Feilenklemme

Kabel für Feilenklemme für EndoPilot Apexkabel

Feilenklemme (zerlegbar)

Feilenklemme (zerlegbar)für Apexkabel EndoPilot

Apex-MessKabel- mit Stecker

Apex-Messkabel mit Stecker für Endopilot jedoch ohne Feilenklemme, Lippenclip, bzw. Kabel für Feilenklemme

Klammer für KF-T3, grün

Klammer für KnochenFilter KF-T3, grün, unsteril

Silikon O-Ring für KF-T3

Silikon O-Ring für KnochenFilter KF-T3 unsteril

Obtura Applikationsnadeln 25ga

Applikationsnadeln Ø 25gafür Obtura Max III BackFill Pistole5 Stück